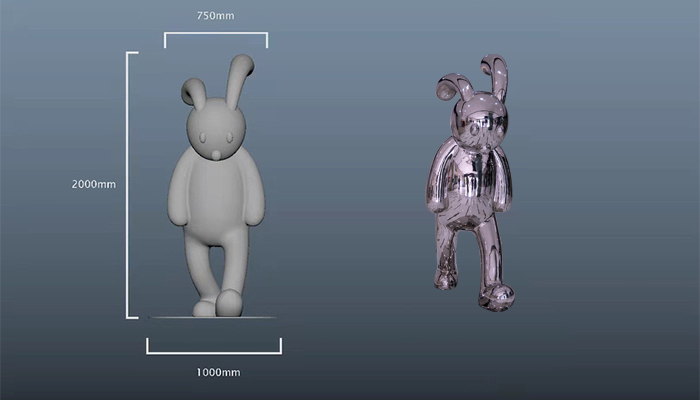

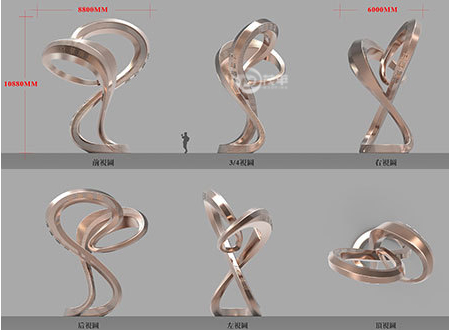

Drawing confirmation

According to the intention drawing or effect drawing and specification size issued by the ordering party, after confirmed by both parties and filed, the sculpture production factory will process and produce.

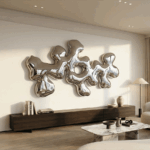

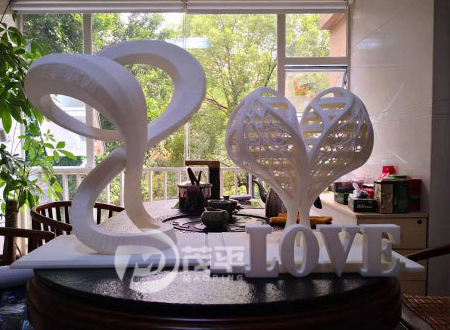

Production samples

The prototype is for the client to confirm the shape of the sculpture and to visualize the sculpture more, and to propose changes to the sculpture.

Make mold and marker

According to the characteristics of the mold, separate different parts into multiple small pieces and mark them, cut the sample after marking, cut into sample paper according to the size and mark it, and cut the material according to the sample paper.

Forging

After the material is opened, the stainless steel sheet is repeatedly forged and repeatedly compared with the mold until it fits perfectly with the mold.

Welding (splicing)

The forged pieces are put together and welded according to the number. Welding usually has fusion welding pressure and brazing, generally using argon arc welding fusion welding method, grinding and polishing after the welding work is completed.

Polishing

Sand the welding joints smoothly, first with coarse sandpaper, then with fine sandpaper, until the splicing joints are smooth and the whole sculpture is integrated.

Surface treatment

The first is the original color thatthe color of the raw material itself; the second is spray paint, commonly used fluorocarbon paint, that automotive paint, according to the production requirements can be sprayed into a variety of colors.